About Tedex

Quality policy

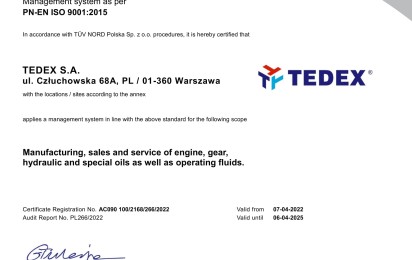

To meet the requirements and expectations of our Customers, our company had implemented Quality Management System and on the 8th September 2000 had obtained a certificate that confirms our compliance with EN ISO 9002 standard in the scope of "Production, sales and service of engine, transmission, hydraulic and special oils and operating fluids".

On 23.10.2003 recertification for compliance of Quality Management System with EN ISO 9001:2000 was conducted. In 2010 EN ISO 9001:2008 certification was conducted with another positive result.

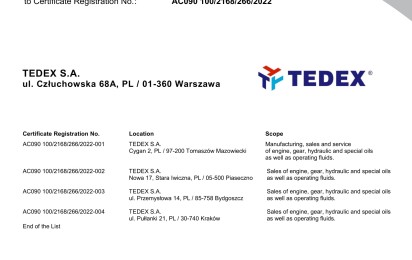

Newest certificate for our Quality Management System compliance with PN-EN ISO 9001:2015 was obtained on the 7th April 2022.

TEDEX for over 30 years guarantees the higest quality of offered oils, greases and operating fluids, stable and timely deliveries, attractive prices and excellent cooperation conditions. Partners and Clients from countries such as: Austria, Belgium, Belarus, China, Georgia, France, the Netherlands, Lithuania, Latvia, Kazakhstan, Germany, Italy, Ukraine and USA had trusted us.

To meet the ever growing requirements of our customers we are concentrating on the constant technical perfection of production and improvement of quality of our products. Product with TEDEX brand have technical approvals of such recognized manufacturers of mechanical vehicles, machines and devices as: Mercedes-Benz, Volkswagen, BMW, Porshe, OPEL, MAN, VOLVO, Deutz, Detroit Diesel, MTU, Renault, Cummins, ZF, Voith and many others.

Tedex products are highly appreciated by a wide group of users including: passenger car owners, service stations and large customers from public transportation, construction, industry and agriculture.

Excellent quality of used materials, modern technologies and high class specialists that understand the real needs of an oil market guarantee perfect usage properties of our oils.

QUALITY CONTROL

At TEDEX Production Plant we have our own laboratory that allows us to analyse all of our products and materials used in production. We are conducting analyses required for quality control of our oils and fluids.

Analyses performed in our lab:

- kinematic viscosity,

- viscosity index,

- density,

- flash point,

- total acid number,

- total base number,

- pour point,

- cleanliness class,

- water content,

- water separability or demusibility,

- foam resistance/stability,

- crystallization temperature,

- pH,

- alkaline reserve,

- copper strip corrosion test.

We are constantly trying to improve our analytical capabilities, so in the last years we have increased our range of analyses by:

- structural viscosity - CCS,

- volatile matter content by Noack's method,

- low-Temperature Viscosity Measured by Brookfield Viscometer,

- sulphated ash content.

Oil service - to evaluate the state of oil in the system is performed in our laboratory as well. They are charge-free for our Cutomers.